Designers Yutao Chen and Yiwen Gu began with the appreciation for pottery craft but decided to push it into unfamiliar territory. The duo felt, what if a robot could take on the role of the potter, not to replace the craft but to expand its possibilities. And this led to their answer in CeraShingle, an architectural facade system that redefines how ceramic can perform, look and behave in contemporary buildings. Learn on SURFACES REPORTER (SR) how digital tools can be used to enhance traditional craft and materials for a tomorrow’s architecture.

Instead of the flat squares that dominate most ceramic cladding, it comprises three-dimensional, robotically 3D-printed clay shingles.

From clay craft to digital fabrication

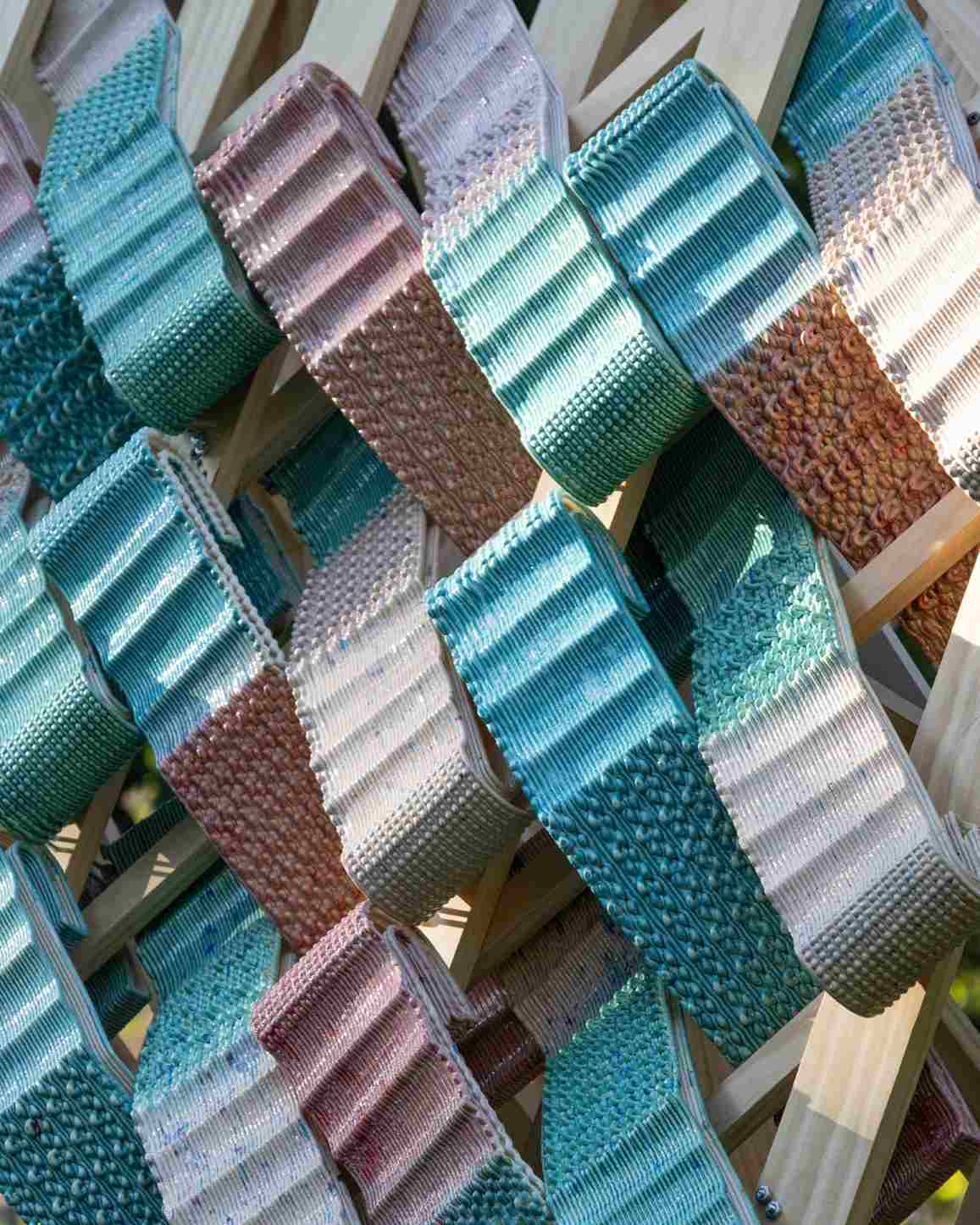

CeraShingle is not a typical tiled facade. Instead of the flat squares that dominate most ceramic cladding, it comprises three-dimensional, robotically 3D-printed clay shingles. These modules carry richly textured surfaces, delicate perforations, organic gradients and intricate geometries that resemble the fluidity of watercolour washes. Each shingle measures approximately 400mm X 130mm and weighs just over a kilogram, thus balancing durability with ease of handling. Installed with a calibrated overlap, these shingles create an animated building skin, one that responds to sunlight, shifts character through the day and transforms depending on the viewer’s position.

The 3D-printing technique places clay exactly where it is required, minimizing material waste compared to conventional subtractive manufacturing.

The system’s innovation lies in its fabrication. Using robotic arms, clay is deposited layer by layer in a controlled parametric workflow. This additive process makes it possible to achieve micro-textures, subtle curves and shadow-catching ribs that conventional mold-based ceramic production cannot replicate. Every shingle can be calibrated to vary in shape, thickness or pattern while still belonging to a coherent, compatible family of modules. The result is a facade that is systematic and expressive, rigorous yet deeply tactile.

Rather than stripping ceramics of its handmade warmth, the designers use computation and robotics to extend the expressive qualities of clay.

New age ceramic facade

One of the most striking achievements of CeraShingle is its ability to dissolve the perceived conflict between digital production and craft. Rather than stripping ceramics of its handmade warmth, the designers use computation and robotics to extend the expressive qualities of clay. The robot becomes a tool that enhances the essence of ceramic artistry and not erases it. Sustainability is an equally critical part of the system’s design. The 3D-printing technique places clay exactly where it is required, minimizing material waste compared to conventional subtractive manufacturing. Chen and Gu also prioritised locally sourced clay and low-temperature glazes, reducing carbon emissions from transportation and firing. Since each module is independent, damaged shingles can be replaced individually rather than trading out an entire panel, extending the lifespan of the facade and keeping embodied carbon low.

Its modular system supports diverse applications, from small installations and interior feature walls to expansive building envelopes.

Aesthetically speaking, CeraShingle offers a fresh alternative to the dominant languages of architectural cladding. Today’s buildings often oscillate between the slick surfaces of glass and metal or brick and stone. CeraShingle occupies a compelling third space with its contemporary yet organic, technologically advanced yet grounded in the earthy warmth of ceramics. Its modular system supports diverse applications, from small installations and interior feature walls to expansive building envelopes.

Image credit: Yutao Chen and Yiwen Gu