China’s Beijing Daxing International Airport—designed by the world-renowned architect Zaha Hadid—incorporated approximately 6.5 lakh sq. ft. of ALUCORE® for the roof.

ALUCOBOND®, the flagship brand of Swiss innovator 3A Composites, is set to further strengthen its footprint in Indian architecture with its advanced composite material, ALUCORE®. Building on its global legacy, ALUCORE® is now available in two innovative variants: ALUCORE® Honeycomb Panels and ALUCORE® ACCP.

“At 3A Composites, our constant endeavour is to introduce advanced façade materials that redefine performance and reliability in architecture,” says Mr. Ranjeet Sharma, CEO, 3A Composites India. “ALUCORE® is another step forward in bringing world-class innovation to the Indian market.”

MR. RANJEET SHARMA President & CEO - 3A Composites India Pvt. Ltd.

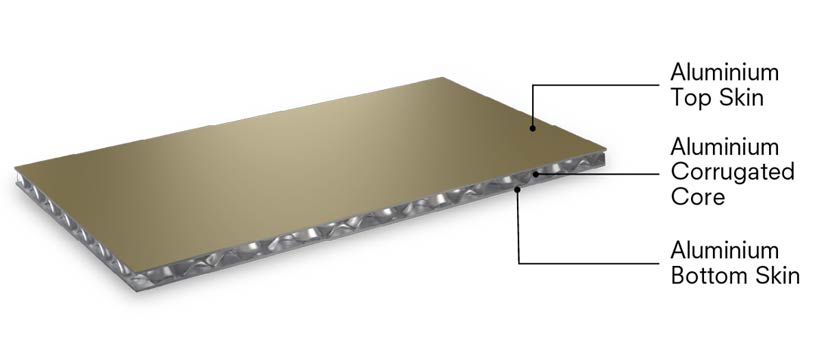

ALUCORE® Honeycomb features an aluminium honeycomb core sandwiched between two aluminium skins, providing exceptional strength-to-weight performance, remarkable rigidity and high load-bearing capacity while remaining lightweight. ALUCORE® ACCP incorporates an aluminium corrugated core between two aluminium skins, offering enhanced structural versatility and durability. Both variants are designed to meet the evolving demands of high-end architectural applications, including façade cladding, roofing, airports, malls, stadiums and commercial complexes.

Manufactured at 3A Composites’ state-of-the-art facility in Ranjangaon, Maharashtra, ALUCORE® is produced on an automated intelligent production line ensuring perfect f latness, uniform quality and superior finish.

The product undergoes a multi-coat, multi-bake PVDF/ FEVE paint process conforming to AAMA 2605 Superior Performance Specifications for exterior applications. It is available in a wide range of finishes, including solids, metallics, vibrants, wood, stone, marble and anodized look, with bespoke color matching to RAL and PANTONE shades for project-specific requirements.

“Through ALUCORE®, we aim to offer architects and façade consultants a material that not only meets but exceeds expectations in strength, sustainability and design flexibility,” shares Mr. Amar Kirale, Associate Vice President Marketing, 3A Composites India. “Its versatility allows architects to push creative boundaries while maintaining superior performance.”

ALUCORE® is 100% recyclable, supporting sustainable building practices. The non-corrosive marine-grade alloy ensures long-lasting durability, superior weather resistance and reliable performance even in demanding environmental conditions. The product meets Class A2-s1-d0 fire classification under EN 13501-1 test standards, making it ideal for high-rise buildings, critical infrastructure and spaces with heavy human traffic where fire safety is essential.

" ALUCORE® has been widely adopted by architects and façade consultants for landmark projects worldwide. In India, it has been used at Vishakhapatnam Airport, Patna Airport, Lulu Mall in Lucknow and Max Towers in NOIDA, among others."

MR. AMAR KIRALE Associate Vice President - Marketing

Globally launched in 1994, ALUCORE® has been widely adopted by architects and façade consultants for landmark projects worldwide. In India, it has been used at Vishakhapatnam Airport, Patna Airport, Lulu Mall in Lucknow and Max Towers in NOIDA, among others.

With its combination of performance, safety, sustainability and aesthetic versatility, ALUCORE® continues to empower architects to design buildings that set new benchmarks for architectural excellence.