Construction activities including concrete are responsible for about 8 per cent to 15 per cent of the world’s carbon dioxide emissions. The building industry, hence, continues to be one of the largest contributors to global warming and climate change. In addition, concrete from demolished buildings, adds to the particulate pollution and is dumped into landfills as the industry lacks an efficient formal system of recycling, especially in India.

What is Green Charcoal Brick?

Engineered as an alternative to concrete, the Green Charcoal Brick is an intersection of material innovation and technology that addresses the issue of rising pollution and temperature. Led by principal researcher Shreyas More, co-founder and co-director, New Materials Research Centre, and Adjunct Faculty-Interior Design, Indian School of Design and Innovation, the research is a development of cutting-edge materials for construction made from charcoal, organic luffa fibres, soil and air to create a biodegradable, lightweight built system that allows the growth of living ecosystems of plants and insects on its surface.

The research is a development of cutting-edge building materials made from charcoal, organic luffa fibres, soil and air.

How does it work?

Its luffa’s fibrous network not only provides strength, flexibility and porosity but also delivers anchorage for plants and acts as thousands of tiny water tanks, thereby cooling the interior environment. With an aim to create more sustainable building materials for the construction industry, the research team is further exploring different treatments to create a variety of bricks. Charcoal, being one of the components of the biodegradable brick mixture which is an adsorbent of nitrates, is used in small portions on the surface. This creates a codependent system where the charcoal adsorbs impurities from the air that serves as nutrition for the plants to feed on.

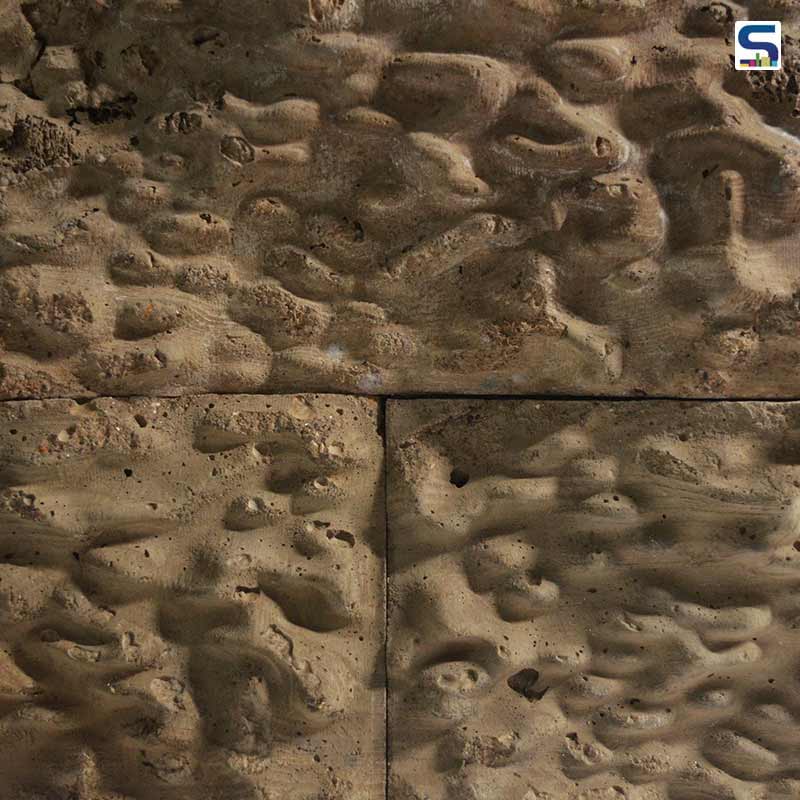

Its organic undulating surfaces are aimed to facilitate better anchorage for plant roots and also to guide them to grow in a certain fashion. The Green Charcoal Brick gives people a sense of material connection with nature which is comforting and a visual connection with natural patterns which are stimulating. By changing the variables and ratios of the material composition, the green charcoal mixture has the potential of opening up diverse applications in built environments.

.jpg)

Characteristics

- Allows biodiversity of plant and insect species

- Allows passive cooling of the interior environment

- Adsorbs impurities from the air

- Replaces metal reinforcements that are found in standard RCC

- Ideal for road curbs, dividers, plastering and cladding materials, construction bricks for compound walls and moderate strength filler walls

- Its material composite has a 90 per cent reduction in the use of coarse aggregate

- 4 per cent reduction in cement v 4 per cent reduction in fine aggregate

- 21 per cent increase in air pockets

- 54 per cent increase in organic matter as compared to a standard concrete block