A rebar as strong as steel for construction made from hemp stalk and bioplastic would soon be a possibility as a team of researchers at Rensselaer Polytechnic Institute (RPI) are developing a composite reinforcing material.

According to project leads – Alexandros Tsamis, professor of architecture, RPI; and Daniel Walczyk professor of mechanical engineering, director of the Manufacturing Innovation Center, RPI – some natural fibres have similar strength to steel for the same weight, so instead of extracting it from the earth, they suggest we grow it.

Steel reinforcing bars play a crucial role when it comes to the structural integrity of building towers. They are used to reinforce cement during construction. However, they are susceptive to moisture and easily rust over time due to the salt in the air. There have been cases where extensive corrosion of steel rebar has caused catastrophic collapses. The researchers suggest that switching to hemp-based materials would not only eliminate the corrosion risk but also extend the life of concrete in buildings and bridges, thereby, reducing the carbon footprint of the building industry.

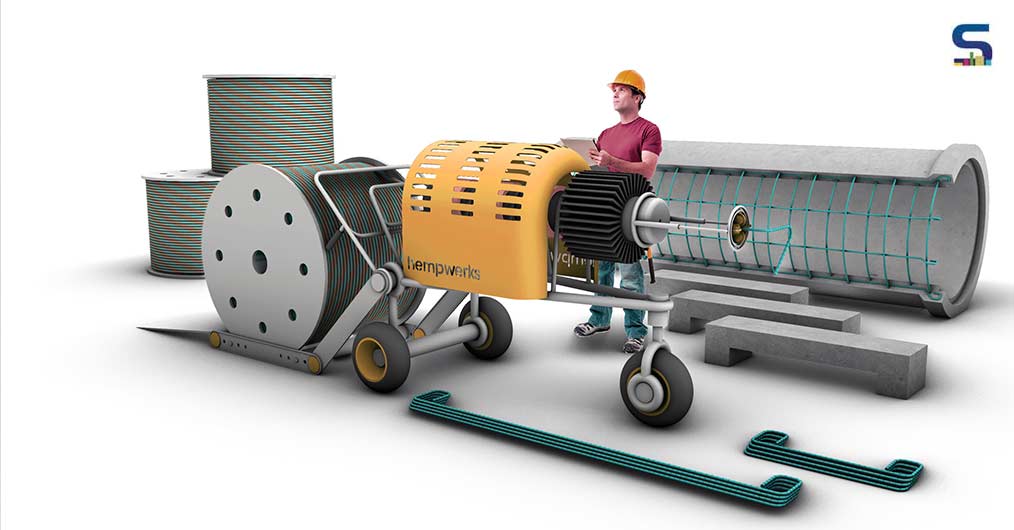

Although hemp rebar is still years away, the team has already started discussing its potential with construction companies. The group aims to attain sustainable practice by introducing hemp to the industry as a carbon footprint-reducing material. To create the rebar, they are using the plant’s stalks in combination with thermoplastics. Reportedly, the material appears like bamboo and is pliable while exhibiting strength comparable to steel. The researchers are yet to test the material in cement as they are focusing on refining its cultivation process and the technology behind it. However, with the help of engineering and science, the team should be able to predict how the rebar will behave.

For this, the fibres are harvested and later put through decortication and de-gumming. During this phase, the fibres are pulled out from the rest of the stalk. By bathing it in a sodium hydroxide solution similar to Draino, some of the compounds that hold it together like natural glue are removed. Thereon, the fibres are run through a machine that pulls them through while melding them together with thermoplastics in the form of a rope. Since the machines used in this process are most likely to damage the characteristics of the fibres, the RPI team has designed a machine and process to overcome this challenge.

The final product, which is much cheaper than standard steel rebar, can be used in infrastructure projects that require cement such as sea walls, pavements and highway ramps.

Image credits: Dezeen