Simon Carroll, a renowned festival set designer, recently unveiled the innovative Hayes Pavilion at Glastonbury festival, challenging the industry’s heavy reliance on polystyrene foam. Designed as a gathering space and a conversation starter, the pavilion explores the potential of mycelium as a sustainable alternative material for elaborate festival sets. Know more about it on SURFACES REPORTER (SR).

The Hayes Pavilion features a 26m long timber frame, resembling the shape of the number six, with one long wall covered in mycelium.

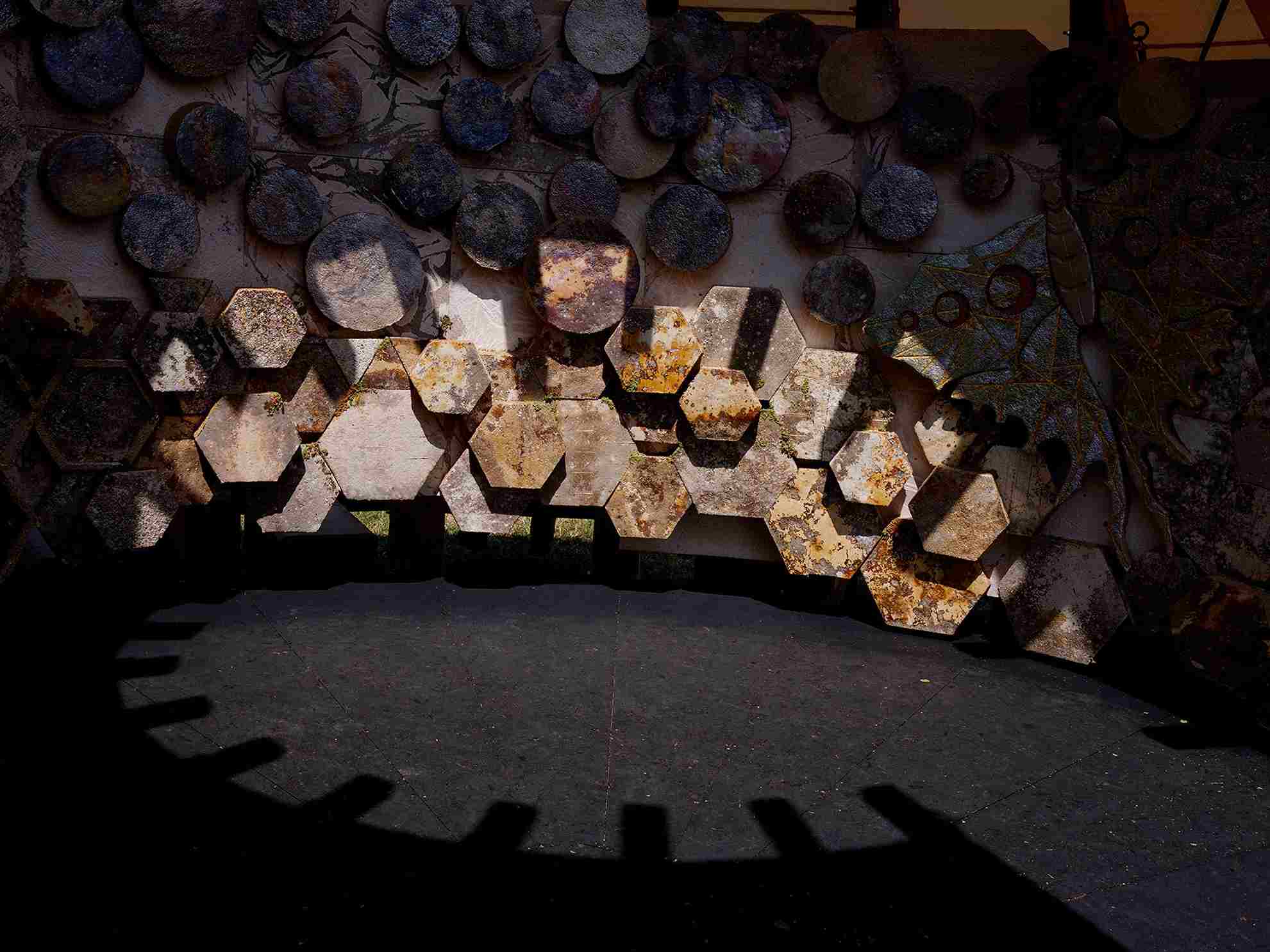

Located in the Silver Hayes field, the Hayes Pavilion features a 26m long timber frame, resembling the shape of the number six, with one long wall covered in mycelium. Mycelium is a biomaterial derived from the root structure of fungi, known for its natural insulation and fire-retardant properties. For the mycelium wall, Carroll used mycelium insulation boards from Biohm and Grown, manufacturers at the forefront of mycelium-based products. These boards were meticulously cut and combined, mimicking the process used by set designers in the film and music industries with polystyrene panels.

For the mycelium wall, Carroll used mycelium insulation boards from Biohm and Grown, manufacturers at the forefront of mycelium-based products.

Carroll, with his two decades of industry experience and notable contributions to Glastonbury, aimed to investigate whether mycelium could replace fossil-based plastics that pose challenges in traditional recycling streams. Recognizing the need for resourcefulness and sustainability, he sought to address the issue of materials ending up in landfills or incinerated after use.

To maximize sustainability, Carroll collaborated with material researchers and set designers from the music, film and TV industries to push the creative boundaries of mycelium. The panels were carefully cut, sanded and assembled using a gelatin-based adhesive, resulting in an undulating three-dimensional surface. A seaweed-based bioplastic coating, developed by industrial designer Leksi Kostur, was applied for colouration. The construction of the Hayes Pavilion prioritized a low environmental footprint, incorporating various reclaimed materials. The exposed timber framing utilized salvaged wood from a 200-year-old Douglas fir that fell during Storm Arwen in Wales. The roof was made from repurposed tents provided by a company specializing in festival marquees.

The roof was made from repurposed tents provided by a company specializing in festival marquees.

Stability was ensured through the use of industrial timber for the decking supports, which hold up the raised oriented strand board (OSB) floors. These floors extend beyond the footprint of Hayes Pavilion, serving as benches for festivalgoers to relax and enjoy the atmosphere. The wooden structure is designed for disassembly, utilizing steel bolts and mounting plates, allowing it to be flat-packed and reused for future festivals.

The wooden structure is designed for disassembly, utilizing steel bolts and mounting plates, allowing it to be flat-packed and reused for future festivals.

After the inaugural edition, the mycelium panels will be retired to make room for other innovations. Unlike polystyrene, these panels can be composted, even with their bioplastic coating, contributing to a more sustainable lifecycle. To assess the project’s overall impact and verify sustainability claims, Carroll enlisted sustainability consultant Pauline Bourdon to conduct a comprehensive carbon assessment of the structure. While Biohm’s mycelium insulation boards are close to regulatory approval, further material development is necessary to adapt them for intricate set designs due to inconsistencies that arise when cutting and sanding the ready-made panels.

Image credit: Chris Hoare