In collaboration with Fab Union, shanghai-based architectural design firm Archi-Union Architects has designed the world’s extremely extensive amended plastic 3D printed architecture, Nanjing Pavilion of Happy Valley Theme Park East Gate. It is a futuristic marvel that allows the humans and robots to enter a new epoch. Its high-dimensioned and super-scaled geometry intended with high efficiency and accuracy showcase the technical progression of automatic printing. The design team precisely created an outdoor UV-resistant colour-modified plastic material, achieving 256 colours with precise parametric colour printing technology. Read on SURFACES REPORTER (SR) to know more about the project:

Also Read: A Furniture Collection Made by Recycling 3D Printed Plastic Waste | BSP

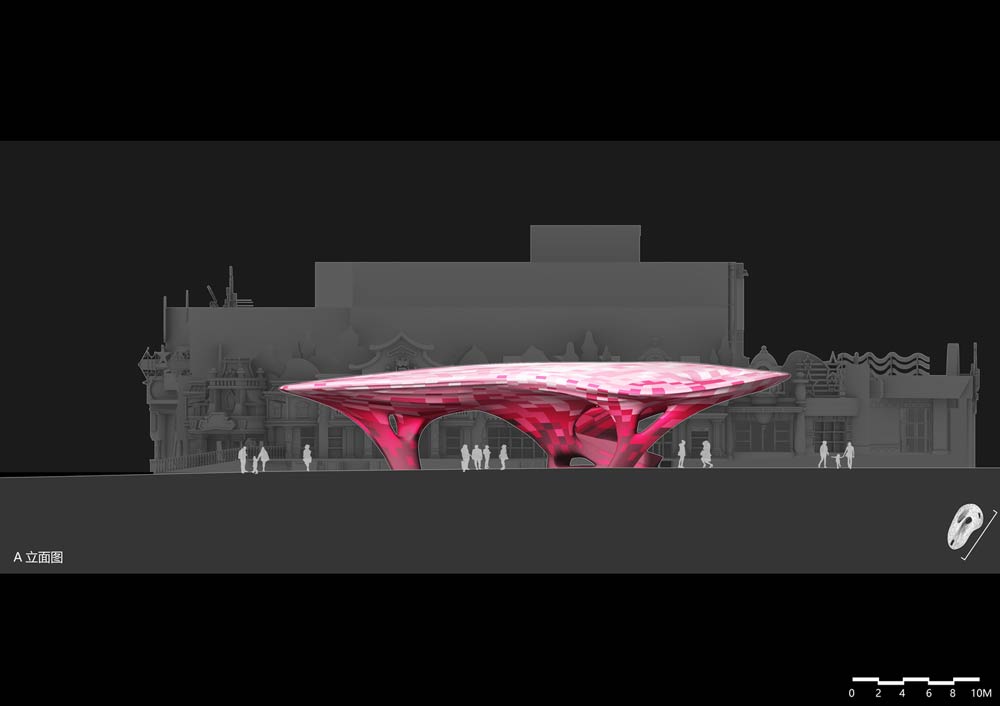

The distinctively customized form of the pavilion perfectly represents Nanjing Happy Valley allowing people to travel from the front plaza to the theme park.

Design Structure

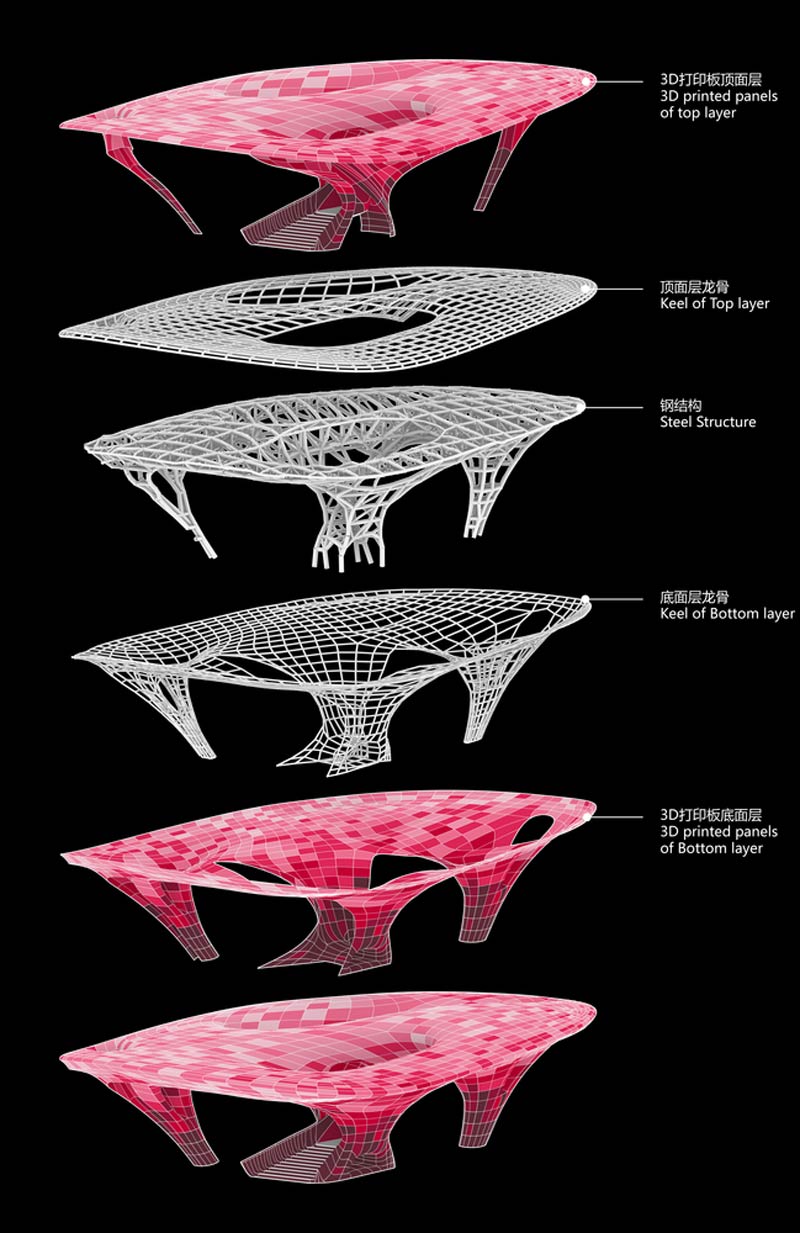

computational geometry helped to shape the hyperbolic multi-layered surface that extends substantially with permeable penetration.

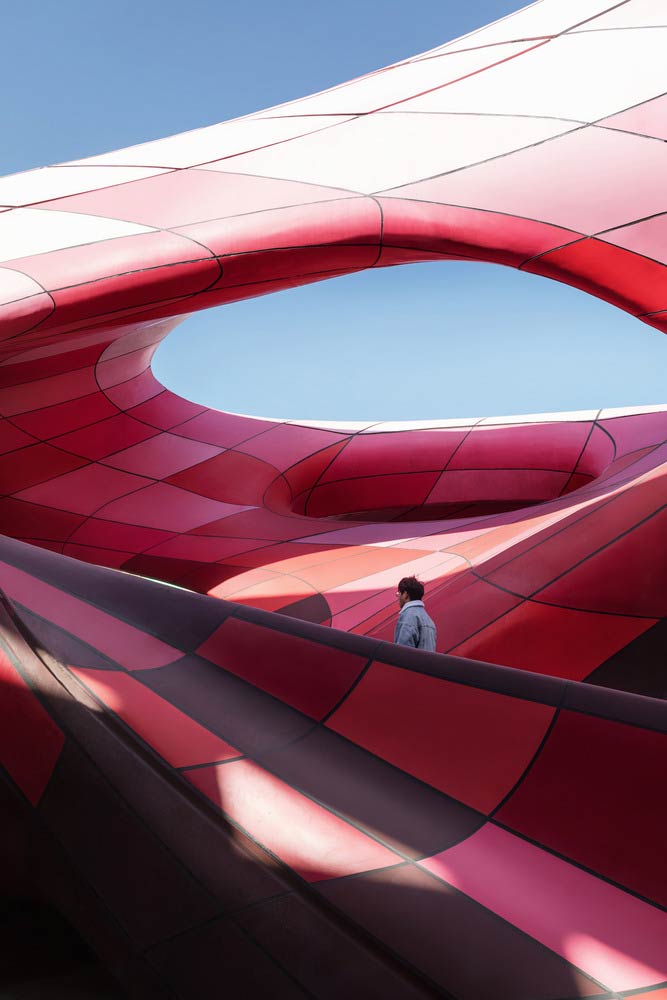

The fantastic structure curves, bends and folds, sprinting the spatial experience as the parts of the structure entwine to weaken the boundary lines of the erection. The steel and modified plastic-printed construction system frame the pavilion. It has a coloured exterior surface enclosed with GRP panels.

The fantastic structure curves, bends and folds, sprinting the spatial experience as the parts of the structure entwine to weaken the boundary lines of the erection. The steel and modified plastic-printed construction system frame the pavilion. It has a coloured exterior surface enclosed with GRP panels.

The east gate extends 52-meters in length and 26-meters in width, projecting over 1352 square meters, and a surface unfolds of 1950 square meters. The heterogeneous irregular overhang span up to 30m, encountering and challenging the design and construction team. 18,300 square meters, the plaza stands as a significant padding and background, a transcendent and welcoming gate, inspiring to invoke a mesmerizing spatial experience for tourists and visitors alike.

Also Read: The Ellipsicoon Pavillion made with woven strands of 100% recyclable polyethylene

Flow, Form and Field

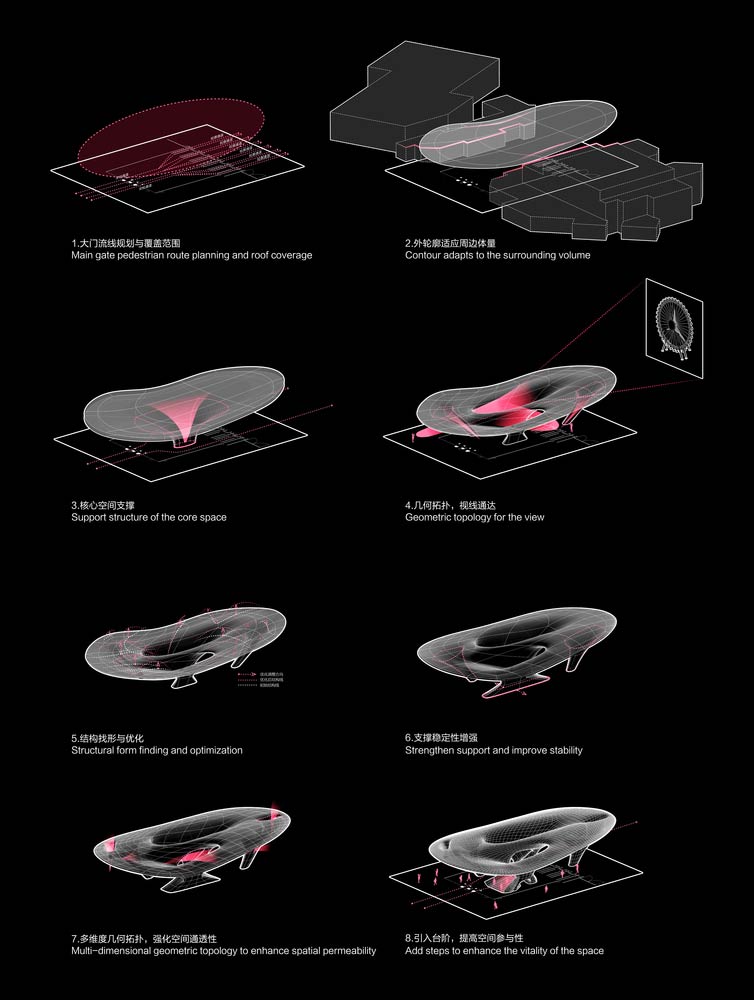

The design concept adorns the factors like form, flow and field. The project comprises the entrance plaza, the east gate and an underground gateway.

The design team marked a group of particles moving in the site to tackle the crowding issue.

Apart from this, several areas in the environment procedures a complex random vector field such as vortex filed, point filed, vector direction field, repulsive force field, and centripetal force field.

Apart from this, several areas in the environment procedures a complex random vector field such as vortex filed, point filed, vector direction field, repulsive force field, and centripetal force field.

Simulating Systems

The simulating systems of the project can transform the environment in reality. During the imitation, the west and east entrances of the pavilion and the square entrance are considered starting points of particle motion.

The computational analysis allowed to influence the hybrid force field on the trajectory of particle motion, and the change in the spatial distribution of the particle population is obtained through computational analysis.

The entrance engages in complex pedestrian flow and various activities as many visitors pass through the ground level of the access. Inward extrusion of the building boundaries on both sides, as the entrance becomes a multi-dimensional topological geometry floating in the site.

Also Read: The 3D Printed Balloon Lamp by Designer Chris Granneberg

The collaboration of computers and architects help to achieve design-based form generation, where computational geometric topological prototypes occur from mathematical surfaces. A simplified equation represents the dazzling calculation.

The collaboration of computers and architects help to achieve design-based form generation, where computational geometric topological prototypes occur from mathematical surfaces. A simplified equation represents the dazzling calculation.

Base Mesh

The mesh in the base supports to generate the structure. The making of a mesh follows the periphery from the geometric parameters. The creation process covers the Surface Skeletonization, Boundary Input, Skeleton Subdivision and Mesh steps. The final topological surface can be applied for actual construction.

The preliminary form needs to be simulated for structural performance, optimization of support location, visual access, and mechanical stability in the gravity field effect, forming the final multi-point support system. The point and line feature the topological mesh to the structural support and force conditions. Hence, the geometric mesh generated based on the topological mesh is consistent with the form and allows the structural system to be incorporated into the parametric design.

Experience Spatial Diversity Through Protruding Staircase

The bulging stairway leads people to experience the spatial diversity of the curvy geometry at various levels and summoning euphoric panoramas. An unusual geometric view frames a specific point of sight passing through the circular cutout in the geometry, reaching the Ferris wheel at the end of the axis of the park.

All visitors from all directions can engross themselves in the three-dimensional connection beyond geometry.

Panel Prefabrication

Each panel is prefabricated and printed by a robot in the factory and transported to the site for modular composite installation with a numbering system. The self-developed FURobot software applied to the 3D program prints algorithms for each panel for machine recognition and real-time feedback.

Also Read: A 3D Printed Bio Based Micro Home for a Post Covid Future by Oliver Thomas and Amey Kandalgaonkar

It helped design team to create a software platform as a model innovation in contemporary architecture. An adaptive inverse deformation algorithm for local geometric models, solve continuous surfaces with unfolded areas up to 1950-meter square into more than 4,000 curved sheets for prefabrication in the factory.

Six Shades of Pink

The pavilion features six shades of pink designed for each panel by the algorithm of coloured pixel collage. These coloured panels, as a metaphor, symbolize the range of activities in the Happy Valley.

The design induces the tourists with a friendly gesture as a magnificent opening. After extensive material testing and performance experimentations, the team accurately developed an outdoor UV-resistant colour-modified plastic material, attaining 256 colours with precise parametric colour printing technology.

Project Details

Project Name: Nanjing Pavilion

Architects: Archi-Union Architects

Photographs: Schran Image, Songkai Liu

Principal Architect: Philip F. Yuan, School of Architecture and Urban Planning (CAUP), Tongji University

Architecture Team Members: Weizhe Gao, Xiangping Kong, Teng Long

Digital Construction: Shanghai Fab-Union Intelligent Engineering Co. Ltd

Digital Construction Team Members:Li Han, Wen Zhang, Liming Zhang, Xuwei Wang, Zhewen Chen, Tao Yu

Structural Design: Xie Yimin Engineering Technology Co.

Lighting Design: Beirui Visual Art Design (Shanghai) Co.

Developer: Eastern Overseas Chinese Town Group (Nanjing) Co., Ltd

City: Nanjing

Country: China

Source: archdaily | www.archi-union.com/

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

Scientists at GE Research 3D Printed A Portable Device That Produces Water Out Of Thin Air

Casa COVIDA is a 3D Printed Home Made From Sand, Straw, Mud, Clay And Other Organic Materials | California | Emerging Objects

And more…