Imagine creating a house and living in it within 24 hours. Living in such a house is now possible. Japanese design studio Serendix Partners has created a home using a 3D printer where people can live within 24 hours. Pursuing a rich and safe Mirai (meaning future in Japanese), Sphere is a 99.17 sqm home that is built in less than 24 hours with an estimated cost of 3 mn yen. Know more on SURFACES REPORTER (SR).

The structure

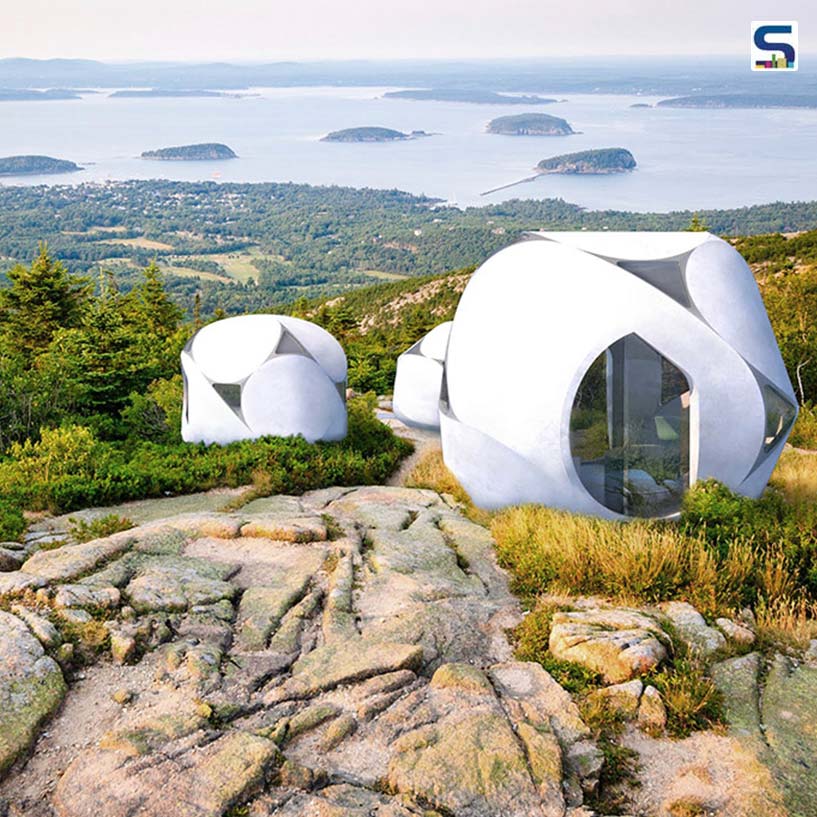

Resonating with the spherical structure, Sphere looks like something out of science fiction. With seven years of work and dedication, Serendix Partners showcased the prototype in 2015. Since then, the structure has witnessed some improvising. The studio has worked with local and international partners to bring the idea from paper to reality.

The structure of the sphere is strong and can be used in various environments. With very few human hands as possible on the project, Sphere has been majorly designed using a 3D printer that uses advanced robotics. The entire frame of the structure is created out of 20 ton concrete. It is the outline of the structure that keeps the Sphere resistant to environmental factors. The construction is solid enough to withstand an earthquake as per the Japanese and European standards.

Under 24 hours

With the aim to provide fast housing solutions in case of emergencies, Sphere had been 3D printed and built in just 23 hours and 12 minutes. The assembly phase took about three hours. However, the process can be much faster if one eliminates painting the exterior which is not necessary in case of emergencies.

With the design benefits of cost savings and no limit to time, the designers claim that in the event of a large-scale natural disaster, Serendix Partners aim to use off-the-grid technology to provide early relief and comfort in the affected areas. Serendix Partners aims to offer Sphere as camping solutions, vacation homes and emergency shelters at the initial stage. Furthermore, the designers will be further developing new functional materials to improve the strength, durability, fire resistance, earthquake resistance, heat insulation and the structure’s beauty.

Image credits: Serendix Partners