With the help of novel polymerization process, MIT chemical engineers have reportedly created a new material that is stronger than steel and as light as plastic, and can be easily manufactured in large quantities.

The 2D polymer, named 2DPA-1, self-assembles into sheets unlike other polymer which are one dimensional. Up until, it was believed that it was not possible to induce polymers to form 2D sheets. However, according to Michael Strano, Carbon P Dubbs Professor, Chemical Engineering, MIT and other senior author of the new study, such a material can be used as lightweight, durable coating for car parts or cell phones, or as a building material for bridges or other structures as well.

However, according to Michael Strano, Carbon P Dubbs Professor, Chemical Engineering, MIT and other senior author of the new study, such a material can be used as lightweight, durable coating for car parts or cell phones, or as a building material for bridges or other structures as well.

A plastic that could take part in construction

Plastic is never used to support a building. However, with this new material that possesses unusual properties, things could change. Polymer includes all plastics. It consists of chains of building blocks which are called monomers. This chain further increases and grows by adding new molecules onto their ends. Upon formation, polymers can then be morphed into 3D objects using injection moulding.

Scientists believe that if polymers could be induced to grow into 2D sheets, they would form extremely strong, lightweight materials. However, it took decades of research and experiments to turn this theory into a reality. The process highlighted that if just one monomer rotates up or down, out of the plane of the growing sheet, the material will begin expanding in 3D and the sheet-like structure will be lost.

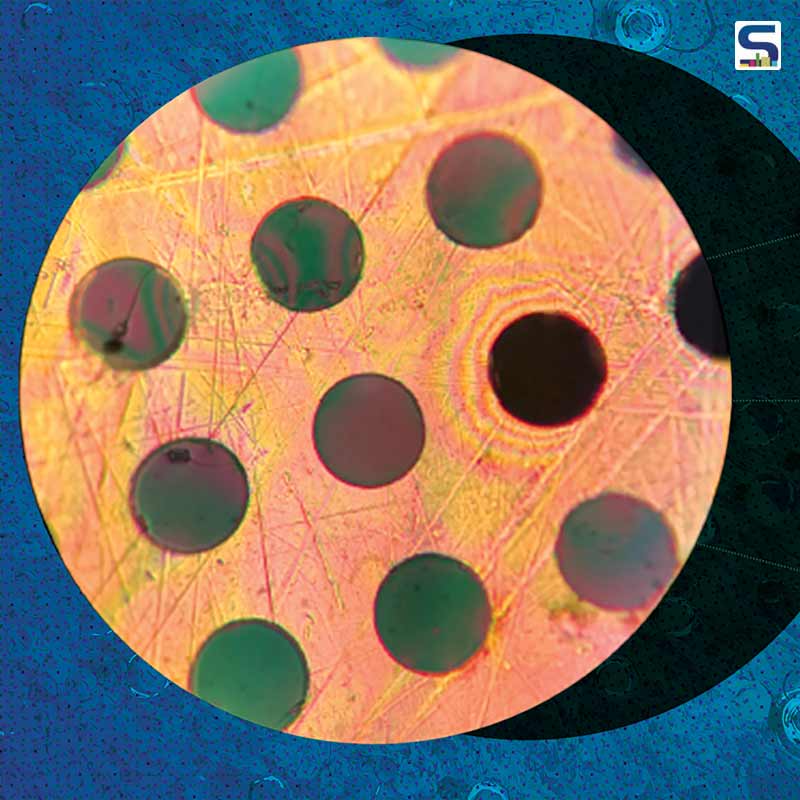

Strano and his colleagues came up with a new polymerization process that allows them to create a 2D sheet called polyaramide. They used a compound called melamine that contains a ring of carbon and nitrogen atoms for the monomer building blocks. These monomers, under the right conditions, can grow in 2D, thereby forming disks. These disks are further stacked up on each other and are held together by hydrogen bonds between the layers, which makes the structure stable and strong. The study is published in the journal Nature.

Research findings

Mass production: The researchers also claimed that since the material self-assembles in solution, it can be made in large quantities by simply increasing the quantity of the starting materials.

Surface coating: Additionally, the researchers also showed that they could coat surfaces with films of the material, which they call 2DPA-1.

Strength: They also found that the new material’s elastic modulus — a measure of how much force it takes to deform a material — is between four and six times greater than that of bulletproof glass. Besides, it yields strength in terms of how much force it takes to break the material, is twice that of steel, even though the material has only about one-sixth the density of steel.

Resistant to gases: Unlike other polymers that are made from coiled chains with gaps that allow gases to seep through, the new material is made from monomers that locks together like LEGOs, restricting the molecules to get in between them. This makes 2DPA-1 impermeable to gases.