Sustainable design has emerged in response to the growing challenges of environmental degradation, global warming, and resource depletion. To reverse our current climate emergency, our transition to becoming carbon negative or, at least carbon neutral is necessary. According to the United Nations Environment Programme, 38 percent of global carbon-dioxide emissions come from buildings, and 17 percent of that number is from the housing. This global greenhouse gas emissions come from the materials used in creating buildings. Some, such as concrete and steel, come with hefty emissions. So, one way to come closer to the sustainable goal is to adopt carbon-negative materials in building construction.

Also Read: The Bricks Used To Create This Elephant Theater Are Made Out Of Animal Waste | Bangkok Project Studio

Ecologically designed buildings are not only more energy-efficient than conventional buildings but they use even 30-50 percent less water. Further, they significantly reduce utility costs and also demand higher re-sale and rental prices.

Although sustainable materials in construction are gaining tremendous popularity within design communities as varied as urban design and planning, architecture, and engineering, the practical approach of it on a large scale is yet far to achieve. SURFACES REPORTER (SR) talked with Haryana-based Dr. Shivdarshan Malik, who says, "On one side, we talk about carbon neutrality, or having a net-zero carbon footprint while on the other side we adhere to building materials that will increase carbon emissions."

Dr. Malik explains with an example, "To prepare a room of 10 by 10, you may require around 6,000 concrete bricks. For manufacturing these number of bricks, one needs to excavate around 18000 kg of clay or soil. After digging, the clay aggregate is heated up to 800-900 degrees celsius which consumes energy and leads to carbon emissions. Then, we require cement and iron. A huge amount of energy is used in producing these building materials. To curb this, it is vital to focus more on sustainable materials in construction.

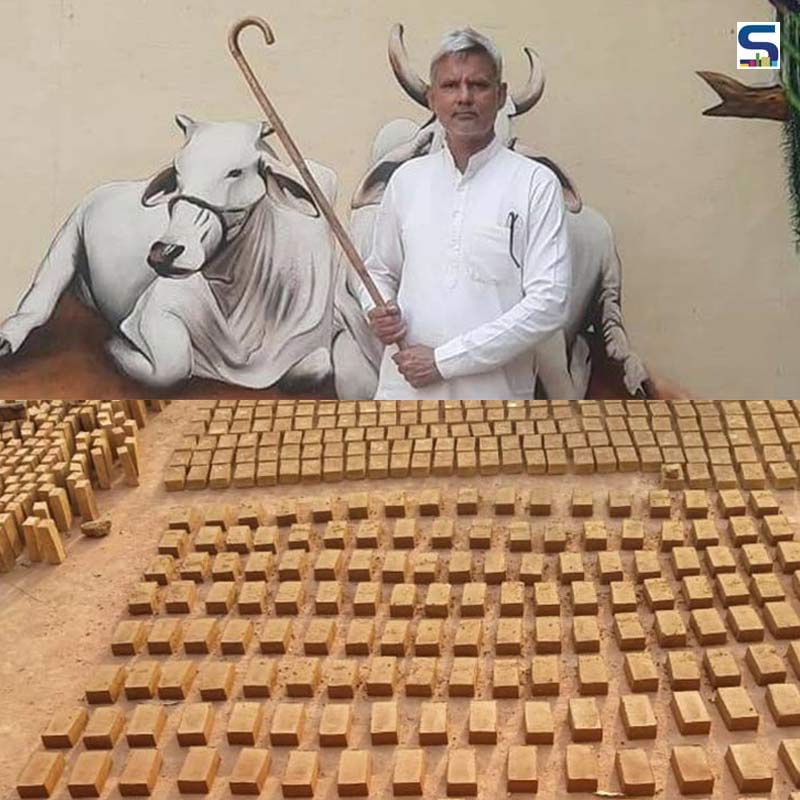

Dr Malik shows the innumerable benefits of cow dung cake

Dr Malik shows the innumerable benefits of cow dung cake

Dr. Malik has innovated eco-friendly building products- Vedic Plaster, Gaucrete Bricks and Natural Paint using cow dung, neem leaves, gypsum, soil, clay, cluster beans, limestone, and other natural materials. These products are carbon-negative and have an immense potential to lower the ambient temperature by 7 degrees Celsius. The plaster created by Dr. Malik works as an insulator and keeps the house warm during the winter months while cool in the summer months.

He says, "Vedic Plaster does not absorb external heat, which helps keep rooms in apartment buildings cooler as compared to those of traditional materials. Thus, these materials significantly cut energy bills and reduce emissions. The other feature of these materials is they absorb pollution and odour." We spoke with the professor to get to know more vital information about the sustainable products created by him, his life journey, inspiration and more.

Meet Dr. Shiv Darshan Malik

Dr. Shiv, who did his Ph.D. in Chemistry from Maharishi Dayanand University in 1995, is originally from Madina village in Rohtak. After completing his doctorate in philosophy, he joined as a professor at Murthal University, Sonipat. He left this job as he did not want to limit his skills and knowledge, and wanted to contribute more to society. His goal was to work for a bigger cause that will bring a significant impact on a large scale.

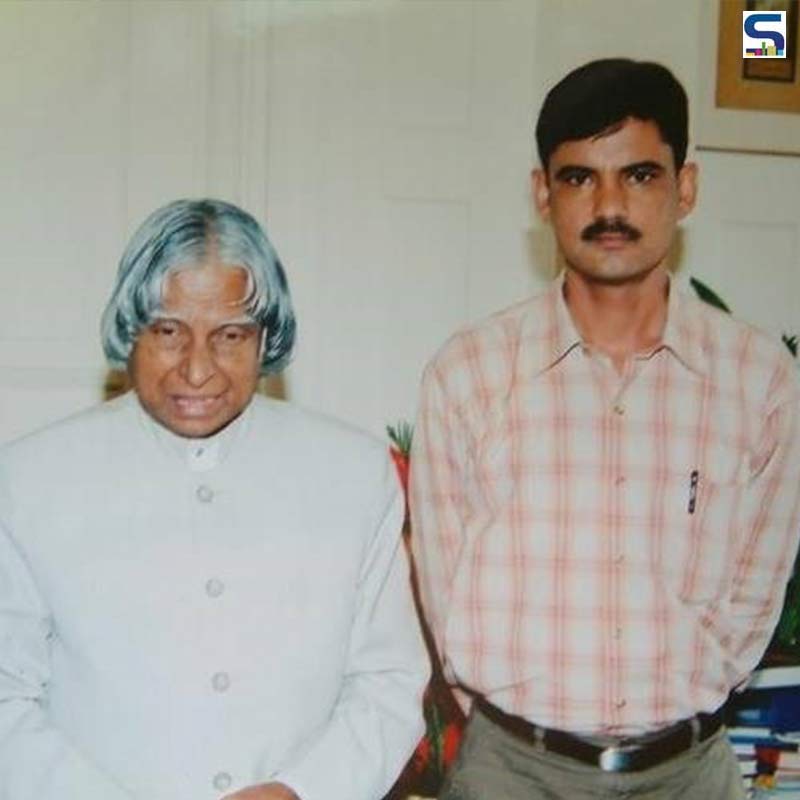

Dr Malik with A. P. J. Abdul Kalam

In 1997, he joined IIT-Delhi, United Nations Development Programme (UNDP), and World Bank. as a consultant. There he worked on several environment and sustainability-related projects. During this time, he also got an opportunity to visit America and England where he studied the ways of making sustainable homes.

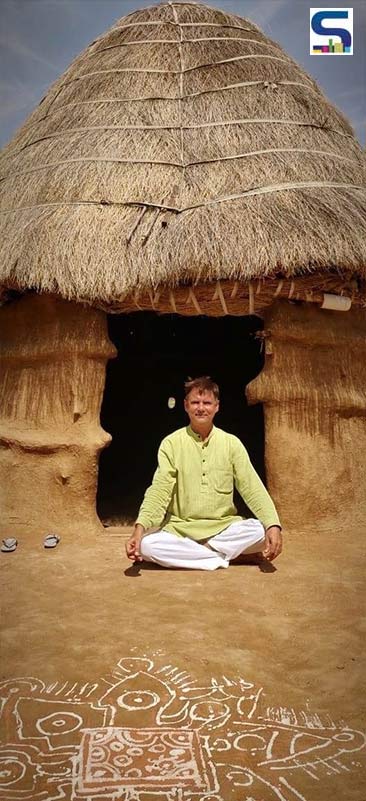

Ram Nath Kovind honouring Dr. S. D. Malik

Dr. Malik has been producing eco-friendly building products from cow dung for the last six years. Dr. APJ Abdul Kalam admired his works and called him Rashtrapati Bhavan in 2004. Many Union ministers also praised his work and supported him. In the year 2019, Dr. Malik has been awarded Haryana Krishi Ratan for his groundbreaking work by President Ram Nath Kobind.

A photo of Dr. Malik With his cows

Currently, Dr. Malik owns four cows, one buffalo and two calves. Further, he has a plant in Bikaner, Rajasthan for the production of plaster and bricks.

What inspired him to create sustainable products?

Talking about the incident of preparing Vedic or Cow Dung Plaster, Dr. Shiv Darshan Malik says, “We had a Kutcha house in the village. My childhood was spent on seeing mother Ved Kaur, swabbing cow dung and yellow clay in the entire house." However, later on, people started using concrete in building construction. "Homes made of concrete heat up like a fuel furnace in summers," he tells Surfaces Reporter. He further adds, " Concrete buildings have a lifecycle of 50 years and later they end up as non-recyclable building waste."

In the year 2000, there were more power outages during the summer. "That was a time when I realized the need and importance of cow dung smeared homes that keep the temperature inside home low even in sweltering summers," he notes. However, he recalled that when his mother used to apply cow dung, cracks usually occurred on the floor. That's why he looks for different ways for creating plaster so that it does not have cracks after use.

Once in America, he saw that Hempcrete is used in building construction. Hempcrete is a biocomposite material that is formed by mixing hemp leaves or Cannabis trees with lime, sand, or pozzolans. That's from where he got the idea of making plaster from cow dung.

During a project in 2005, he worked on using agricultural waste and dry cow dung to generate clean energy. He observed even after the establishment of a 'dung gas plant' in their village, the large amount of dung is either wasted or used only for making cow dung cakes. The village had tons of cow dung which were going to waste as people had stopped the traditional practice of plastering their houses with cow dung. As a result, the use of dung has decreased compared to the past. Further, the saturated cow dung was emitting methane and other greenhouse gases. He planned to use this wasted cow dung for creating Vedic Plaster and Gaucrete bricks.

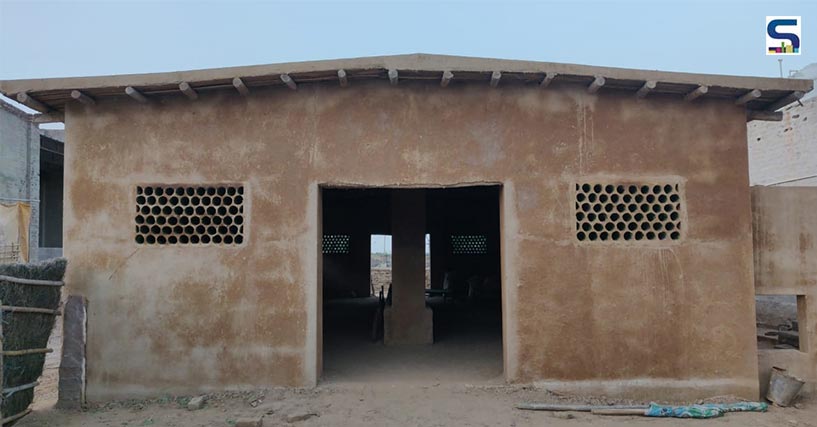

Vedic plaster and natural paints used in his office in Bikaner

After some research in 2006, he made the Vedic Plaster as an alternative to conventional plaster used in concrete structures to smooth walls. He used cow dung, clay, soil, gypsum, neem leaves, cluster beans, limestone and other natural materials to create the plaster that helps to create breathable homes. He created his office near Sheela bypass Chowk with the use of Vedic plaster and natural paints. He said that it can be used in creating multi-storeyed buildings as well.

"Cow dung has a thermal insulating material that makes it apt for constructing buildings as it keeps the structures cooler during summer months and warmer in winters. While talking to us, he said even in this scorching summer heat of 43 degrees Celsius, with all fans turned off except a small cooler, the temperature inside my office is as low as 28-31 degrees Celsius," explains Dr Malik.

Plastic bottles used in the windows of Dr Malik's Bikaner Office. As the area faces hot and dry westerly desert wind, this innovative technique helps to keep the interiors cool. He kept the narrow portion of the bottle inside so that the compressed air reaches inside and maintains its temperature.

According to him, one can use this unique plaster on existing modern concrete houses too. For this, you just need to scrape off the existing plaster and replace it with the Vedic aggregate.

Vedic plaster prepared by Dr. Malik has been used till now in around 20,000 homes in India. Odisha-based entrepreneur Pradeep Agrawal said that he layered his home recently with the Vedic plaster and now they no longer require air conditioning even in these scorching summers. He says that the results are incredible and would help him to save a minimum of Rs 8,000 a month on electricity bills.

Also Read: Demolished Bricks and Concrete Intertwine to Form Custom Designed Products | A Waste Epiphany | SR Decor

Preparation of Vedic Products

Dr Malik uses 10 percent cow dung, 15 percent sandy soil and 70 percent gypsum to prepare Vedic Plaster. Moreover, 5% guar gum and lemon juice powder have been added to the mixture. Guar gum offers lubrication to plaster. Its specialty is that it smells when water is poured.

Dr Malik shows dried cow dung cake in this photo

Dr Malik shows dried cow dung cake in this photo

Natural paints are formed using lime, coloured clays and guar gum. While the formation of Gaucrete bricks requires cowdung and pond soil. These bricks are not burnt at high temperatures and do not need water for manufacturing. The natural sun-drying process is enough to prepare these bricks. These bricks are sturdy and equivalent to traditional bricks.

.jpeg) The professor does not use LPG in the kitchen but uses cow-dung cakes as fuel for preparing food. He says," LPG is a fossil fuel and is responsible for increasing CO2 in atmosphere whereas cow dung is a renewable fuel and not responsible for global warming and climate change."

The professor does not use LPG in the kitchen but uses cow-dung cakes as fuel for preparing food. He says," LPG is a fossil fuel and is responsible for increasing CO2 in atmosphere whereas cow dung is a renewable fuel and not responsible for global warming and climate change."

Dr Malik claims that these bricks will not catch fire for 73 minutes. He tested a brick of 10 mm thickness by keeping it on the gas for 5 minutes. He says that as the thickness of the brick increases, the fire rating will also increase. These bricks have also been seen by putting them in water and they do not dissolve in it.

Advantages of Vedic Plaster and Gaucrete bricks Over Traditional Plaster and Bricks

The first and foremost advantage of Vedic building products is that they do not cause any harm to the environment and cause no carbon emissions.

They are also capable of absorbing air pollution. Vedic plaster is made of all-natural ingredients that filter out harmful particulate matter size 2.5 and 2.10 from the indoor air and ever absorb harmful radiation of different types of towers and gadgets.

House-made using Gaucrete bricks and Vedic plaster will remain cool in summer and warm in winter. It also can absorb harmful fumes and bad odour. There is no dampness. The home will be radiation-proof and last many years longer than the houses constructed using cement. Vedic Plaster is not affected by insects and does not nourish mould growth of fungus. This does not pose any health-related issues and is hence recommended in even hospitals and clinics.

House-made using Gaucrete bricks and Vedic plaster will remain cool in summer and warm in winter. It also can absorb harmful fumes and bad odour. There is no dampness. The home will be radiation-proof and last many years longer than the houses constructed using cement. Vedic Plaster is not affected by insects and does not nourish mould growth of fungus. This does not pose any health-related issues and is hence recommended in even hospitals and clinics.

How much do they cost and from where to buy

The weight of a brick made of cow dung is up to 1.78-2.2 kg. The production cost of it is around five rupees per brick. Vedic plaster costs between 12-15 Rs per square feet. Trained labour can only apply these products appropriately on the wall. For this, the professor offers four days of training on his premises in Bikaner.

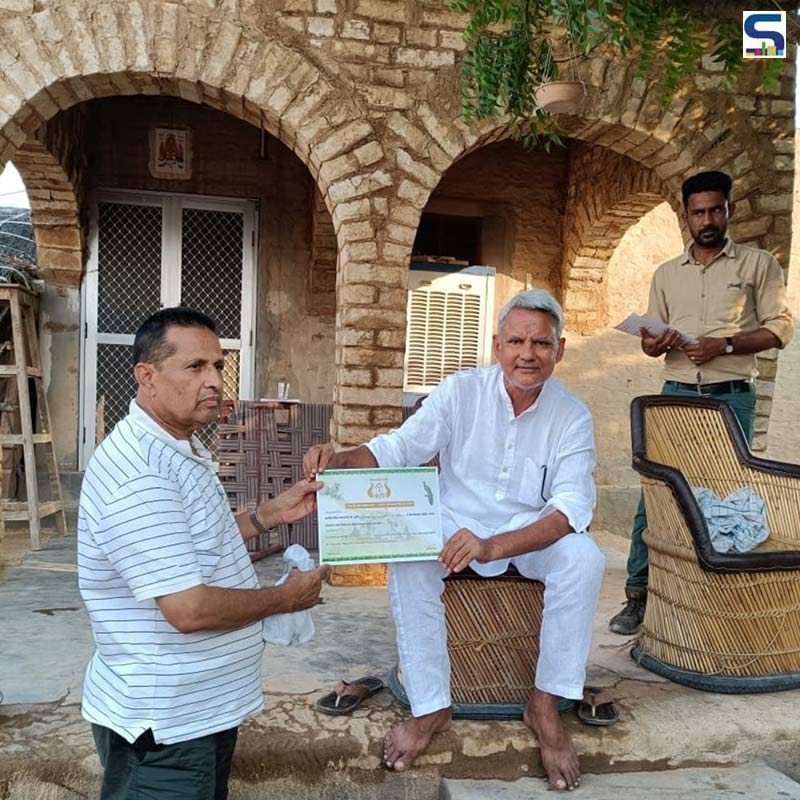

Professor Srinivasan- a PhD in Computer Engineering from IIT Madras in Gobarpathology training camp receiving his training certificate from Dr Malik

You can place an order online to get Vedic Plaster and Vedic Paints. However Gaucrete bricks are not supplied online. The professor states, "My purpose for creating these products is to promote the local economy, local resources and mitigate environmental pollution. But supplying products to other parts of the country may require transportation that consumes oil and produces air pollution. Further, it will bump up the price of the product as the transportation cost will add to it." Hence, the professor wants people to create their own gaucrete bricks. He has trained many people to make Gaucrete bricks so far.

Also Read: Colourful Bricks Made from 90% Construction Waste without using Kiln Firing | K-Briq

Things Made From Cow Dung

For creating plaster, when the first time I entered the cowshed to collect the cow dung I got stunned to see that the cows are standing in 1-1 and a half feet of dung. At that time, I realised the worth of this natural material that is getting wasted. I talked with my associate Vani Goyal (B.A.L.L.B) and with her support created gaucrete," recalls Dr. Malik.

Eco-friendly bricks made out of cow dung and other natural materials

Eco-friendly bricks made out of cow dung and other natural materials

He in collaboration with Vani Goyal has created Gaucrete using desi cow dung which is a complete building material that can be used for making mortar and bricks. Furthermore, after changing Gaucrete composition, it can also be used in making plaster, flooring and also be used in the roof as a substitute to lanter.

For making gaucrete bricks, one needs to own cows for the cow dung which is an essential constituent in the creation of these bricks. Hence, the professor emphasizes cow protection and preserving the environment through his products. He also notes, "the ponds which were once the lifeline of the villages are dried and disappeared now. I believe that the use of pond soil in making these products will help in the revival of existing dead ponds. This will also assist in solving the water scarcity situation in many villages."

Apart from Gaucrete, Dr. Malik in partnership with Dr. Manoj Doot creates natural colours using lime, coloured clays and guar gum. These paints costs 20 percent less than the colours available on the market. Besides, flower pots, phone stands, and furniture are also being made from cow dung.

Challenges faced

There were many challenges. The foremost and sadist one is posed by the mindset of the people towards cow dung. According to people, the use of cow dung in homes is not up to their standard. Further, the lack of institutional support from concerned authorities in the ministry was another challenge. It took a good amount of time to gain the trademark for the product. Moreover, carving a niche for the product was also a significant challenge.

"Convincing distributors, training team members on how to develop skill sets of labours – the vital link in this process showed expected challenges. Generating awareness and building trust towards the product once again made the path trying to tread. Though, the way was challenging but not impossible to achieve because eventually, the sustainability criteria played for the product. To operate at a large scale and meeting consumer demand on time was challenging initially but now lessons are learned through experience," says Dr. Malik.

"Convincing distributors, training team members on how to develop skill sets of labours – the vital link in this process showed expected challenges. Generating awareness and building trust towards the product once again made the path trying to tread. Though, the way was challenging but not impossible to achieve because eventually, the sustainability criteria played for the product. To operate at a large scale and meeting consumer demand on time was challenging initially but now lessons are learned through experience," says Dr. Malik.

In a nutshell

Sustainable design is not a luxury, it is a necessity. The entire world is facing adverse impacts of climate change. And global issues require global platforms that support and facilitate the distribution of such local and eco-friendly products. To mitigate the harmful impacts of usual building materials, architects and designers must come together to promote and reward innovative sustainability solutions. They should apply their creative talents and acumen to create these innovations stylish and aesthetically pleasing to attract consumers toward making "green" choices, and thus help in shaping a sustainable, low-carbon future.

Photos and Info Courtesy : Dr Shiv Darshan Malik

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

Researchers Turn Agricultural Waste Into Ecofriendly Bricks To Solve Rural Housing Crisis Bio-Brick

A Biodegradable Construction Material That Claims to Be an Alternative to Concrete Blocks - Green Charcoal Bricks

The Man Behind Worlds 1st Fully Automated Brick-Making Machine That Produces 300 Bricks a Minute | SR Interview

and more...