One man’s trash is another man’s treasure. While big companies generate environmental hazards and add a ton to the mountain of trash, local businesses and young creative heads have started hunting down sustainable options. On a similar road is interdisciplinary designer Disharee Mathur who has come up with a brilliant idea of resurrecting discarded sanitaryware products by crafting them into beautiful Jaipur Blue Pottery. In conversation with SURFACES REPORTER (SR), Mathur talks about her journey, the project and more…

Wasted Wonder

Growing up in Jaipur, Mathur has always been intrigued and amazed by Indian crafts which she observed to be a part of her everyday life. “I was intrigued to see the gap between the richness of traditional practices in India and the products in the international market,” she adds. With an urge to find an intersection between traditional craft and scientific innovations, Mathur gave birth to Project NewBlue.

By turning rejected sinks and toilets into artistic wonders, the young designer is reinventing the century-old craft of Jaipur Blue Pottery. The project aims at drawing parallelism between the traditional Blue Pottery and material innovations keeping in mind its sustainable factor. The project lifts up craft preservation with new-age co-designing techniques.

With the Jaipur Blue Pottery community and Dr Himmat Singh Kushwaha of the Material Research Centre at the Malviya National Institute of Technology, Mathur co-designed material composites using ceramic waste to add on to Indian craft’s legacy of innovating with local abundance. Calling two aspects of her innovation as A Synonym and Antonym for Jaipur Blue Pottery, where Synonym resonates the material’s compressive strength and Antonym opens new architectural markets to the craft, Mathur and her team identified sanitaryware waste in the local areas and morphed it into sustainable material for Project NewBlue.

According to Mathur, Project NewBlue is the second technological intervention in Jaipur Blue Pottery since the 1860s. “India has the largest craft concentration in the world, yet only 2 per cent of the global handicraft market share. These numbers affect remote craft communities across the subcontinent. The Jaipur Blue Pottery craft was studied to understand the scenario from the ground up,” informs Mathur.

Innovative Material

The NewBlue material is made with the addition of waste as an ingredient in the traditional Blue Pottery process. Since the material can be made and used in traditional craft workshops, the traditional craft practices and manufacturing process has been left untouched. The ceramic is fired only once at 790-800o Celsius.

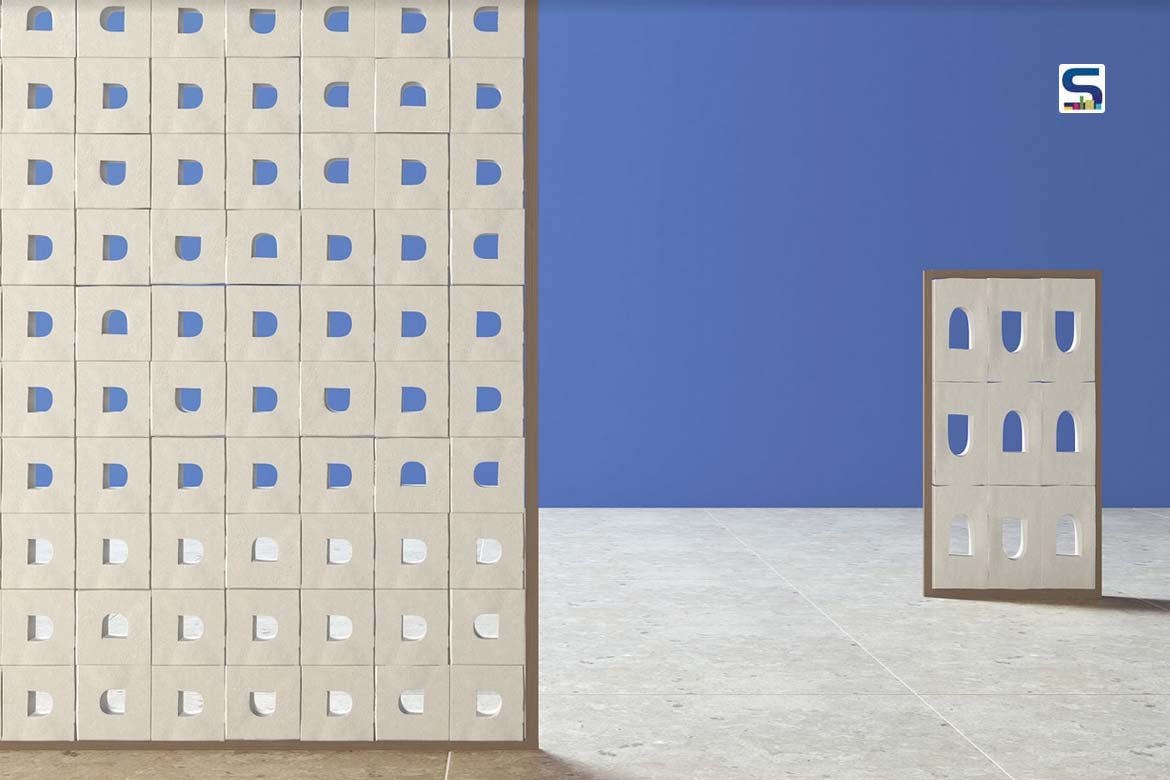

The Synonym material is embodied as an end-table using a new composition from the existing traditional moulds, highlighting its newly acquired strength and scale of the material which is made with ceramic waste. Embodied as passive cooling architectural tiles in collaboration with Industhan Ceramics, the Antonym deletes the toxic glaze from the recipe to make the ceramic body strong and porous.

Green Future

With over six months of research and creating prototypes, Mathur has successfully nailed in turning one man’s trash into an ecological wonder. Her interest in creating a green future with an admiration for traditions and enthusiasm for scientific materialism has helped in reducing the strain on landfills that houses discarded non-biodegradable sanitaryware waste. Although material deterioration and product development challenged the project, Mathur with the aid of Neerja Blue Pottery opted for a participatory design approach to innovate a new craft future. “I learned how to navigate these channels as four institutions across two countries came together to make Project NewBlue a reality,” says Mathur.

The intervention becomes a catalyst in making craft units eligible for state-economic opportunities as contributors to local waste management. Mathur believes that recent craft preservation efforts have been geared towards preserving practices as artifacts, rather than enterprises in the economy. Project NewBlue strives to nurture traditions of the past while crafting out the waste of the present.

About the designer

Disharee Mathur is an interdisciplinary designer working across products, interactions and interiors. She entered the field of design as a painter, with a fascination for bringing ideas from paper to reality. Her work has spanned across industries from office design, workplace strategy, and hospitality design to innovation strategy, exploring realms of sustainability, well-being and cultural conversation. Disharee received her degree in Bachelor of Fine Arts in Interior Design at the Savannah College of Art and Design (SCAD) and has worked with internationally renowned interior architecture firms including Studio O+A (San Francisco, USA) and Gensler (Bangalore, India).